Gas and Industrial Fans

Date of issue:2022/12/2 14:14:40 Number of Views:

Gas and Industrial Fans:

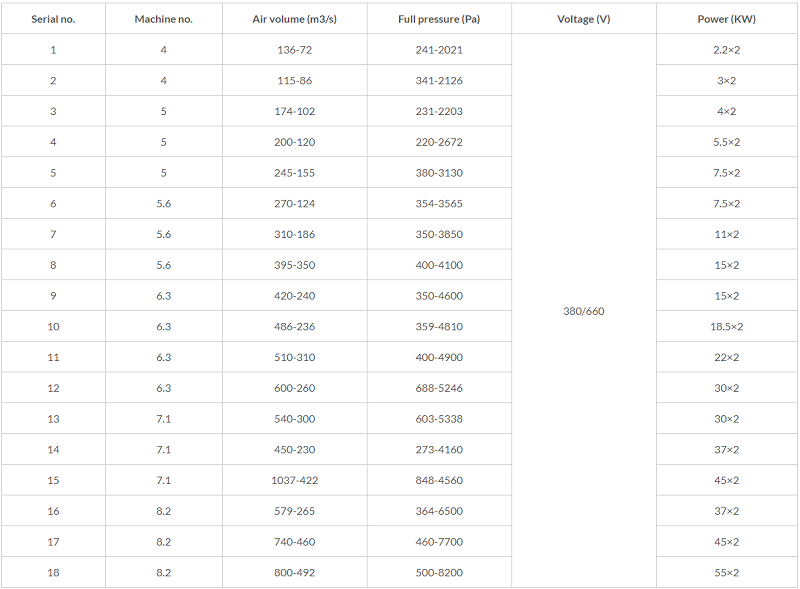

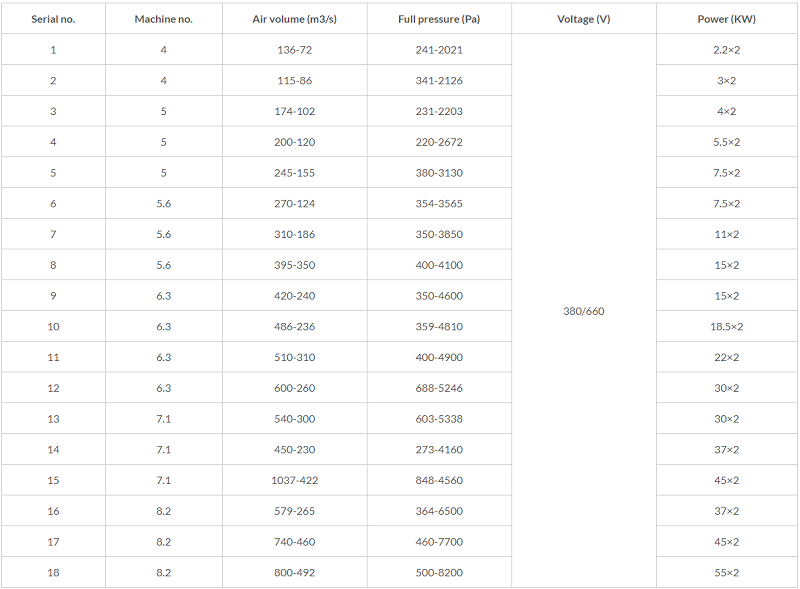

In order to meet the needs of coal mines, the mine energy saving promotion station of the Ministry of Metallurgy invented the explosion-proof patent technology of the extraction type main fan of the coal mines. The materials used in the machine have passed the friction spark test of the Test Center of China Coal Research Institute Chongqing Branch and achieved the explosion-proof requirements. The explosion-proof performance of the whole machine has passed the explosion-proof inspection of the China National Quality Supervision and Test Centre for Explosion Protected Electrical Products. It introduces the FBCDZ (formerly BDK62) series of coal mine ground explosion-proof extraction type counter-rotating axial flow ventilator, which has better performance, more specifications and larger coverage. The product is subject to the standards of Q / ZFJ001-2004 the Technical Conditions of the FBCDZ (formerly BDK62) Series of Coal Mine Ground Explosion-proof Extraction Type Counter-rotating Axial Flow ventilator.

For the problem that if there is no muffler device, Gas and Industrial Fans noise is large?

As long as the fan is running, there will be noise, and the noise of the gas and industrial fans are also a specification to measure the quality of a fan. When mining fans are working, the noise that occurs mainly includes aerodynamic noise and mechanical noise. Among them, aerodynamic noise is the most intense, the main component of mine fan noise. Aerodynamic noises include rotational noise and eddy current noise. Rotational noise is a dipole sound source, mainly related to the number of blades and rotational speed, and its intensity is roughly proportional to the 10th power of the speed. The intensity of eddy current noise is proportional to the 6th power of the airflow velocity. From the mechanism and characteristics of mine fan noise, it can be seen that the optimal aerodynamic performance design is the fundamental method to obtain the lowest aerodynamic noise. In addition, the reasonable design and matching of the flow parts can not only obtain high efficiency, but also control its noise. By increasing the aerodynamic load of the blade grid, reducing the circumferential speed as much as possible, appropriately reducing the hub ratio, reducing the axial speed, unequal spacing moving blades and reasonable number of blades, reasonable axial clearance and radial clearance, the method of bending blades can be used to reduce fan noise. The above is to control noise from the sound source, and in order to prevent the transmission of noise, noise can be controlled from the propagator pathway. For local fans, among the noise emitted by mining fans, the noise intensity radiated at the inlet and outlet is the largest. The most effective measure to suppress this part of the noise is to install a muffler at the inlet and outlet of the mine fan. At present, there are many mufflers on the market, and perforated plate mufflers are more used for cyclones. The sound-attenuating material is sandwiched between the inner cylinder and the outer cylinder of the fan, and the inner cylinder is a micro-perforated plate structure, and the inner cylinder can be withdrawn from the outer cylinder to facilitate the replacement or cleaning of the sound-attenuating material. The installation of the anechoic material is shown in Figure 4

For the mine underground explosion-proof induced draft fan, it is generally necessary to install a sound insulation cover or cover fan room. The installation of sound insulation cover is to surround the mine fan with a closed cover, the hood can add a sound-absorbing structure, the noise is reflected many times in the hood, most of the sound energy is absorbed, so that the noise is greatly reduced. The site adopts more covered fan rooms, and measures such as sound insulation and mufflers are taken in the room, so that although the noise in the machine room is larger, the external noise is much smaller.

Gas and Industrial Fans:

In order to meet the needs of coal mines, the mine energy saving promotion station of the Ministry of Metallurgy invented the explosion-proof patent technology of the extraction type main fan of the coal mines. The materials used in the machine have passed the friction spark test of the Test Center of China Coal Research Institute Chongqing Branch and achieved the explosion-proof requirements. The explosion-proof performance of the whole machine has passed the explosion-proof inspection of the China National Quality Supervision and Test Centre for Explosion Protected Electrical Products. It introduces the FBCDZ (formerly BDK62) series of coal mine ground explosion-proof extraction type counter-rotating axial flow ventilator, which has better performance, more specifications and larger coverage. The product is subject to the standards of Q / ZFJ001-2004 the Technical Conditions of the FBCDZ (formerly BDK62) Series of Coal Mine Ground Explosion-proof Extraction Type Counter-rotating Axial Flow ventilator.

For the problem that if there is no muffler device, Gas and Industrial Fans noise is large?

As long as the fan is running, there will be noise, and the noise of the gas and industrial fans are also a specification to measure the quality of a fan. When mining fans are working, the noise that occurs mainly includes aerodynamic noise and mechanical noise. Among them, aerodynamic noise is the most intense, the main component of mine fan noise. Aerodynamic noises include rotational noise and eddy current noise. Rotational noise is a dipole sound source, mainly related to the number of blades and rotational speed, and its intensity is roughly proportional to the 10th power of the speed. The intensity of eddy current noise is proportional to the 6th power of the airflow velocity. From the mechanism and characteristics of mine fan noise, it can be seen that the optimal aerodynamic performance design is the fundamental method to obtain the lowest aerodynamic noise. In addition, the reasonable design and matching of the flow parts can not only obtain high efficiency, but also control its noise. By increasing the aerodynamic load of the blade grid, reducing the circumferential speed as much as possible, appropriately reducing the hub ratio, reducing the axial speed, unequal spacing moving blades and reasonable number of blades, reasonable axial clearance and radial clearance, the method of bending blades can be used to reduce fan noise. The above is to control noise from the sound source, and in order to prevent the transmission of noise, noise can be controlled from the propagator pathway. For local fans, among the noise emitted by mining fans, the noise intensity radiated at the inlet and outlet is the largest. The most effective measure to suppress this part of the noise is to install a muffler at the inlet and outlet of the mine fan. At present, there are many mufflers on the market, and perforated plate mufflers are more used for cyclones. The sound-attenuating material is sandwiched between the inner cylinder and the outer cylinder of the fan, and the inner cylinder is a micro-perforated plate structure, and the inner cylinder can be withdrawn from the outer cylinder to facilitate the replacement or cleaning of the sound-attenuating material. The installation of the anechoic material is shown in Figure 4

For the mine underground explosion-proof induced draft fan, it is generally necessary to install a sound insulation cover or cover fan room. The installation of sound insulation cover is to surround the mine fan with a closed cover, the hood can add a sound-absorbing structure, the noise is reflected many times in the hood, most of the sound energy is absorbed, so that the noise is greatly reduced. The site adopts more covered fan rooms, and measures such as sound insulation and mufflers are taken in the room, so that although the noise in the machine room is larger, the external noise is much smaller.

- Previous:Mining Fan

- Next:Mine Explosion-proof Blower