Stainless Steel Centrifugal Fan

Date of issue:2022/12/5 10:18:15 Number of Views:

Stainless Steel Centrifugal Fan,

The model 9-19\9-26 high-pressure centrifugal ventilator has the advantages of high efficiency, low noise, flat performance curve and wide areas of high efficiency compared with the same type of ventilator at home and abroad.

The structure of the stainless steel centrifugal fan is small, the appearance is beautiful and atmospheric, especially the structure is very stable, and the motor operation is safer and more stable. The centrifuges produced by professional manufacturers will reach a very stable standard in terms of functional characteristics to meet the work needs of different industrial environments, and the following will be a comprehensive analysis of the specific advantages of centrifuges in work.

1. The working performance is very stable

Since the centrifuge research and development technology began to innovate and improve, breaking through the limitations of traditional technology, it has better advantages in terms of function, and can also make stable working performance get better play. As long as it is operated and used in the correct way, it can have a safer and more efficient use effect, and can also ensure a longer service life, meet the work needs of special environments, and the meaning of the application is better displayed.

2. Suitable for various occasions

Centrifuges have a very safe and efficient use effect in a variety of different working occasions, a wide range of applications, simpler and more convenient operation, which can bring work advantages to the work, waste too much time to avoid wasting too much labor costs. While ensuring the working effect, it can also make the operation safer and the stability of operation can be guaranteed, which can avoid unexpected hidden dangers in special occasions.

Scope of application:

Generally speaking, the ventilator is used for forging furnace and high pressure forced ventilation, which also can be widely used for conveying materials, conveying air and the air of non-corrosive unnatural, non-viscous substances. The medium temperature shall not exceed 280℃, but it can be made into high temperature ventilator according to the requirements of the users. The dust and hard particles contained in the medium shall not be more than 150mg/m3.

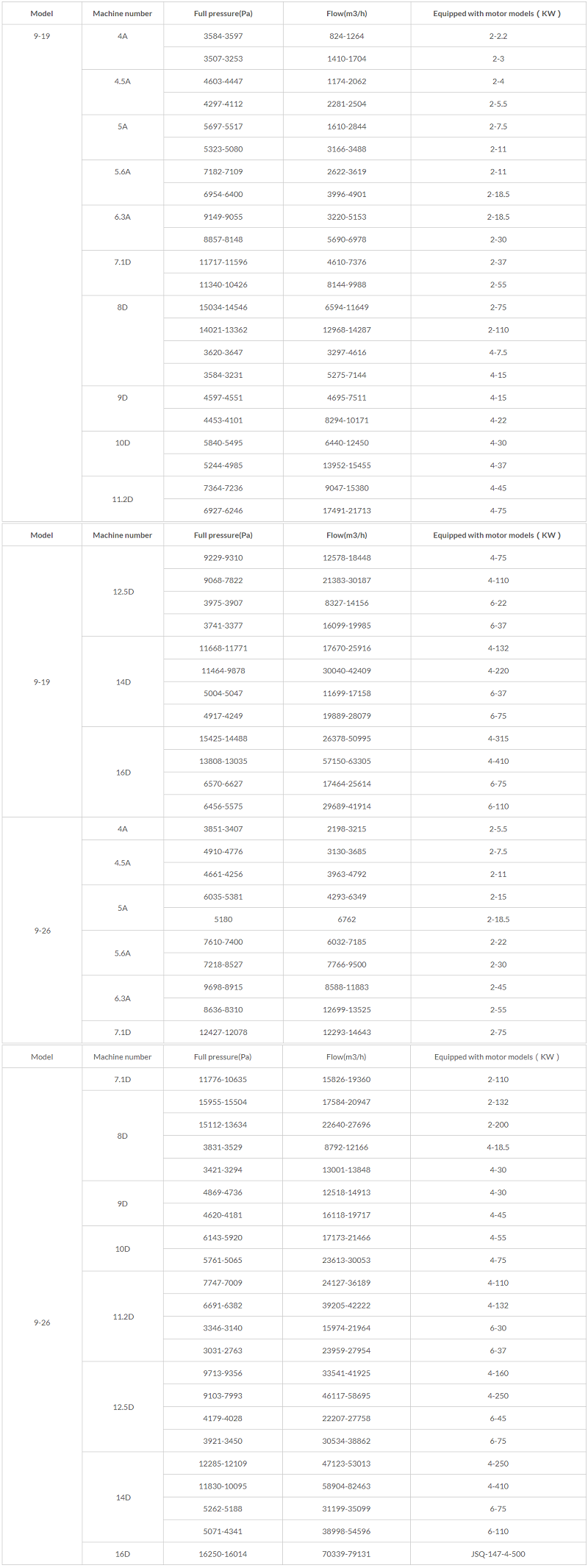

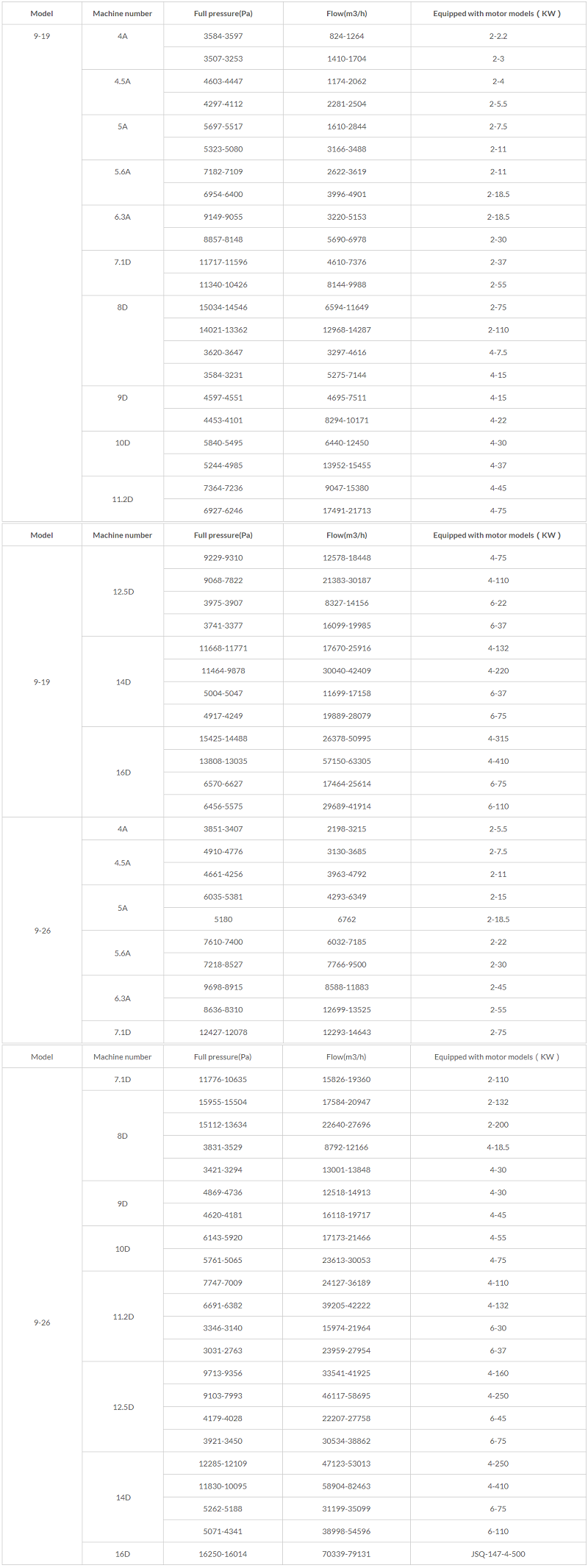

The ventilator is a single-inhalation type machine with a total of 13 models: 4, 4.5, 5, 5.6, 6.3, 7.1, 8, 9, 10, 11.2, 12.5, 14 and 16. It can be made into six angles of left and right rotation 0 degree, 45 degrees, 90 degrees, 135 degrees, 180 degrees and 225 degrees. It has two transmission modes of type A and type D.

Stainless Steel Centrifugal Fan,

The model 9-19\9-26 high-pressure centrifugal ventilator has the advantages of high efficiency, low noise, flat performance curve and wide areas of high efficiency compared with the same type of ventilator at home and abroad.

The structure of the stainless steel centrifugal fan is small, the appearance is beautiful and atmospheric, especially the structure is very stable, and the motor operation is safer and more stable. The centrifuges produced by professional manufacturers will reach a very stable standard in terms of functional characteristics to meet the work needs of different industrial environments, and the following will be a comprehensive analysis of the specific advantages of centrifuges in work.

1. The working performance is very stable

Since the centrifuge research and development technology began to innovate and improve, breaking through the limitations of traditional technology, it has better advantages in terms of function, and can also make stable working performance get better play. As long as it is operated and used in the correct way, it can have a safer and more efficient use effect, and can also ensure a longer service life, meet the work needs of special environments, and the meaning of the application is better displayed.

2. Suitable for various occasions

Centrifuges have a very safe and efficient use effect in a variety of different working occasions, a wide range of applications, simpler and more convenient operation, which can bring work advantages to the work, waste too much time to avoid wasting too much labor costs. While ensuring the working effect, it can also make the operation safer and the stability of operation can be guaranteed, which can avoid unexpected hidden dangers in special occasions.

Scope of application:

Generally speaking, the ventilator is used for forging furnace and high pressure forced ventilation, which also can be widely used for conveying materials, conveying air and the air of non-corrosive unnatural, non-viscous substances. The medium temperature shall not exceed 280℃, but it can be made into high temperature ventilator according to the requirements of the users. The dust and hard particles contained in the medium shall not be more than 150mg/m3.

The ventilator is a single-inhalation type machine with a total of 13 models: 4, 4.5, 5, 5.6, 6.3, 7.1, 8, 9, 10, 11.2, 12.5, 14 and 16. It can be made into six angles of left and right rotation 0 degree, 45 degrees, 90 degrees, 135 degrees, 180 degrees and 225 degrees. It has two transmission modes of type A and type D.

- Previous:Anti-corrosion Centrifugal Fan

- Next:Centrifugal Fan for Brick Kiln