Mine Axial Flow Fan Press-In Fan

Date of issue:2022/12/5 15:49:49 Number of Views:

Mine Axial Flow Fan Press-In Fan:

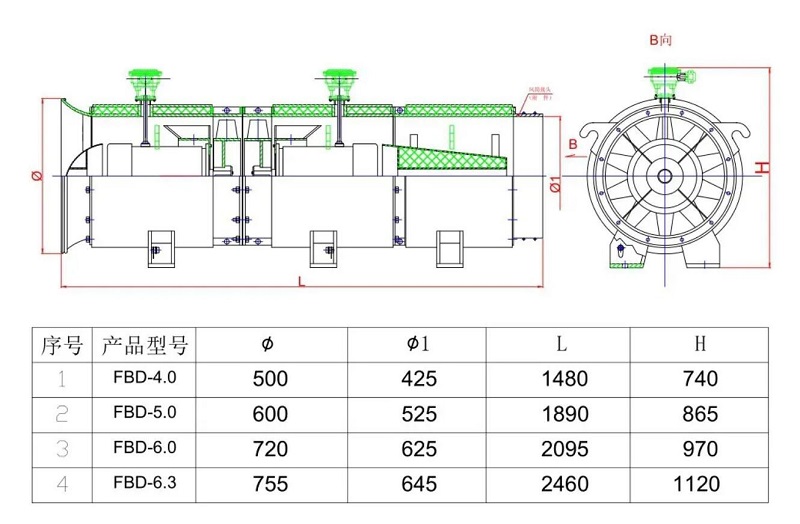

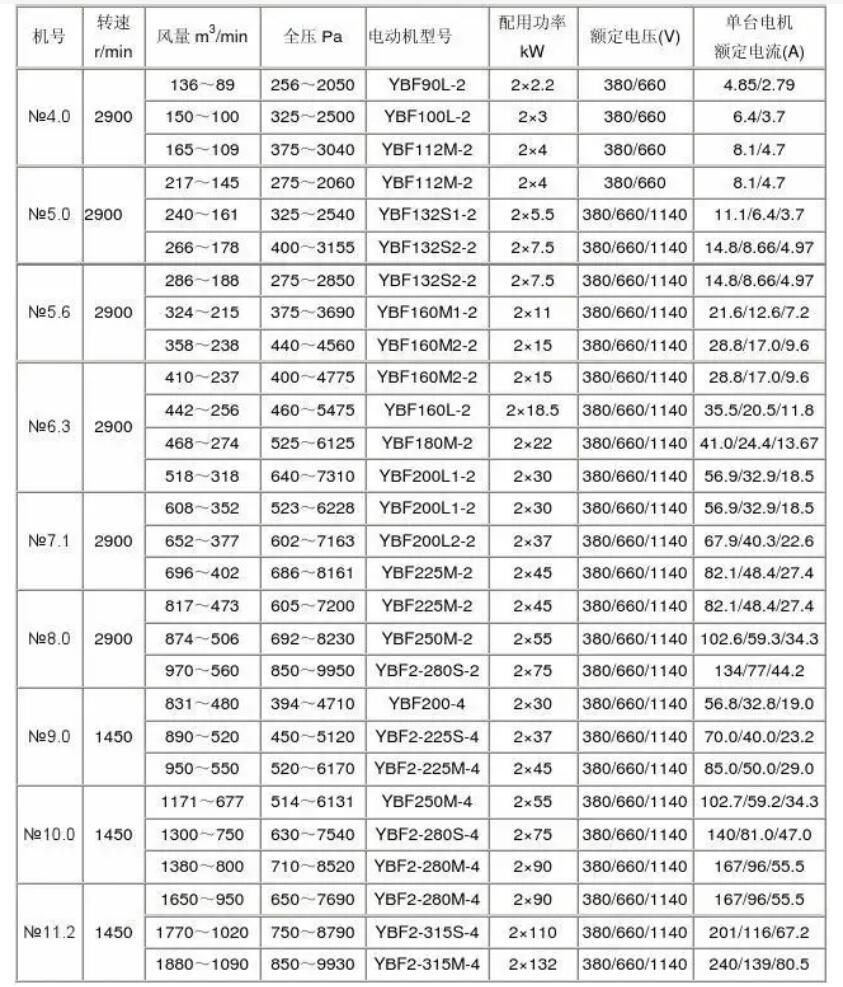

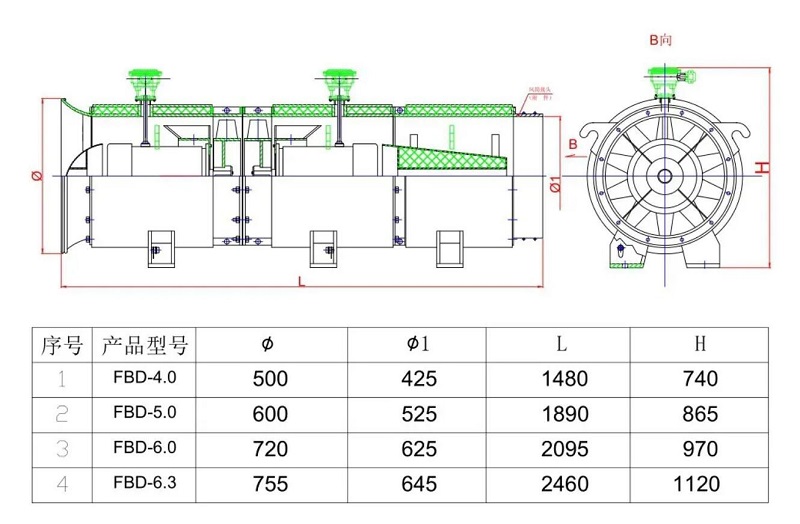

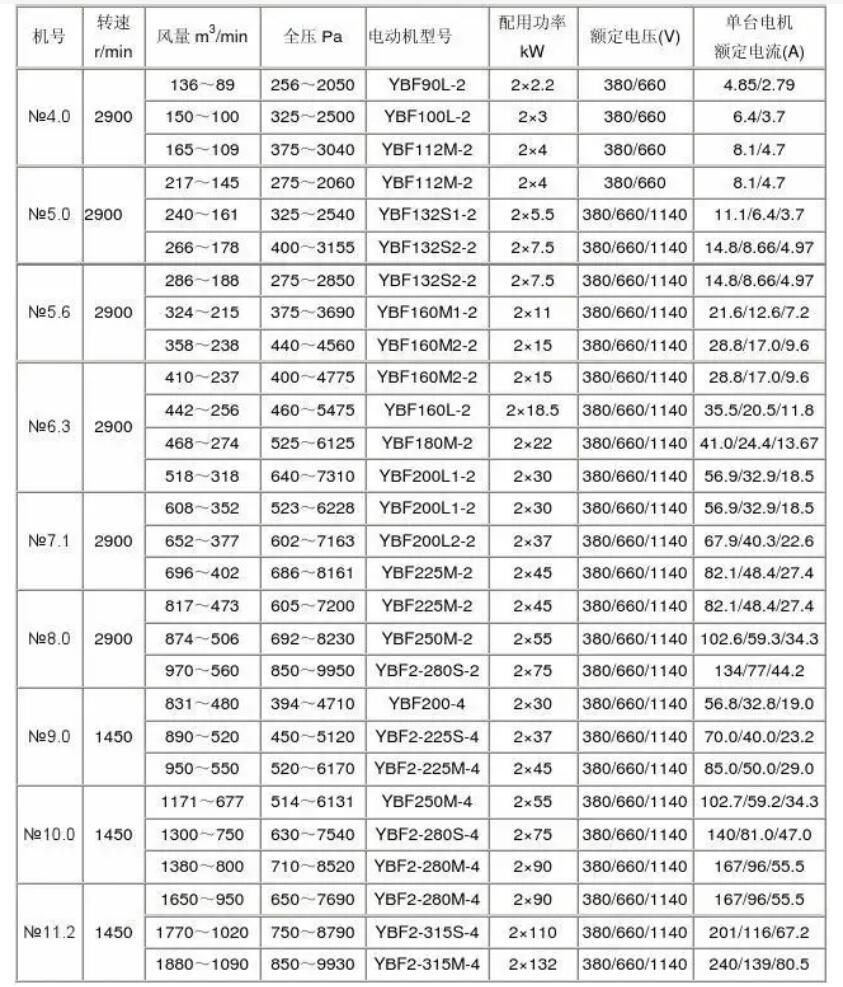

FBD mine explosion-proof press-in counter-rotating axial flow local fan FBD6.3/30×2 explosion-proof fan is mainly used for non-coal mine underground, which can be used for medium and long distance ventilation of mining face. The fan has the characteristics of reasonable structure, complete specifications, high efficiency, obvious energy saving effect, low noise and long air supply distance. The length of the roadway is less than 2000m, and the fan can be used for normal air supply, which reduces the labor intensity of workers and saves ventilation time. It is an ideal equipment for local ventilation in non-coal mines.

Mine Axial Flow Fan Press-In Fan working conditions:

1. The air temperature is -15℃~+40℃;

2. The relative humidity is not more than 95% (+25℃);

3. The altitude does not exceed 1000 meters;

4. No strong vibration and corrosive gas, etc.;

5. Installed in the air intake tunnel of coal mines where there is a danger of gas.

Mine Axial Flow Fan Press-In Fan Features

1. The blade adopts the domestic ternary flow theory to carry out aerodynamic performance design, and adopts the imitation airfoil-shaped arc plate twisted blade, which has high aerodynamic efficiency, wide high-efficiency area and remarkable energy-saving effect. And make the air flow smoothly through the fan at high speed to ensure the safe operation of the fan.

2. The outsourced duplex muffler device has ultra-low noise characteristics and has a significant effect on changing the noise environment of the confined space in the well.

3. The main body adopts the steel plate group welding structure, and the blades and the inside of the casing are treated with anti-corrosion and moisture-proof, so that the fan can run in a humid environment for a long time, effectively solving the problem of corrosion caused by other conditions to the fan.

4. The matching motor is a Y series three-phase asynchronous motor with a voltage level of 380V. The fan can be equipped with a non-stop oil-filling device to ensure that the fan can inject and discharge oil during operation, and ensure the long-term reliable and safe operation of the motor in harsh environments.

When the mining fan is running, it is mainly responsible for monitoring the electrical and mechanical current, which is not only a sign of the fan load, but also a forecast of some abnormal accidents. In addition, always check whether the vibration of the electromechanical and fan is normal, whether there is friction and abnormal noise. Care should be taken to monitor whether the fans running in parallel are operating in a surge state. In normal operation, the machine should be stopped immediately and inspected if the following conditions occur

Mine Axial Flow Fan Press-In Fan:

FBD mine explosion-proof press-in counter-rotating axial flow local fan FBD6.3/30×2 explosion-proof fan is mainly used for non-coal mine underground, which can be used for medium and long distance ventilation of mining face. The fan has the characteristics of reasonable structure, complete specifications, high efficiency, obvious energy saving effect, low noise and long air supply distance. The length of the roadway is less than 2000m, and the fan can be used for normal air supply, which reduces the labor intensity of workers and saves ventilation time. It is an ideal equipment for local ventilation in non-coal mines.

Mine Axial Flow Fan Press-In Fan working conditions:

1. The air temperature is -15℃~+40℃;

2. The relative humidity is not more than 95% (+25℃);

3. The altitude does not exceed 1000 meters;

4. No strong vibration and corrosive gas, etc.;

5. Installed in the air intake tunnel of coal mines where there is a danger of gas.

Mine Axial Flow Fan Press-In Fan Features

1. The blade adopts the domestic ternary flow theory to carry out aerodynamic performance design, and adopts the imitation airfoil-shaped arc plate twisted blade, which has high aerodynamic efficiency, wide high-efficiency area and remarkable energy-saving effect. And make the air flow smoothly through the fan at high speed to ensure the safe operation of the fan.

2. The outsourced duplex muffler device has ultra-low noise characteristics and has a significant effect on changing the noise environment of the confined space in the well.

3. The main body adopts the steel plate group welding structure, and the blades and the inside of the casing are treated with anti-corrosion and moisture-proof, so that the fan can run in a humid environment for a long time, effectively solving the problem of corrosion caused by other conditions to the fan.

4. The matching motor is a Y series three-phase asynchronous motor with a voltage level of 380V. The fan can be equipped with a non-stop oil-filling device to ensure that the fan can inject and discharge oil during operation, and ensure the long-term reliable and safe operation of the motor in harsh environments.

When the mining fan is running, it is mainly responsible for monitoring the electrical and mechanical current, which is not only a sign of the fan load, but also a forecast of some abnormal accidents. In addition, always check whether the vibration of the electromechanical and fan is normal, whether there is friction and abnormal noise. Care should be taken to monitor whether the fans running in parallel are operating in a surge state. In normal operation, the machine should be stopped immediately and inspected if the following conditions occur

- Previous:Mine Ventilation Blower

- Next:Coal Mine Fan